Chuck can not move

Chuck parts damaged

Decomposition of chuck and replacement parts

Chuck can not move

Chuck sliding parts

Decomposition of chuck burr removing oil

Chuck can not move

The chuck body accumulate too much trash

Chuck decomposition cleaning oil re combination

Chuck can not move

The rust of parts

Decomposition to rust

Chuck can not move

A1 direct mounting type taper inconsistent

Check the connection end surface fitting correction

Chuck can not move

Connecting dimensions connected properly

Re measurement renovation connecting disc

Work with sliding phenomenon

Claw shaped size with the work of clamping diameter incompatibility

The method of forming the correct prevail, again forming

Work with sliding phenomenon

Insufficient clamping force chuck

Check whether to grasp the correct torque fastening

Work with sliding phenomenon

The cutting force is too large

The calculation of cutting force, to confirm whether the appropriate readjustment

Work with sliding phenomenon

Rotary speed is too high

Rotary speed reduced to standard

Work with sliding phenomenon

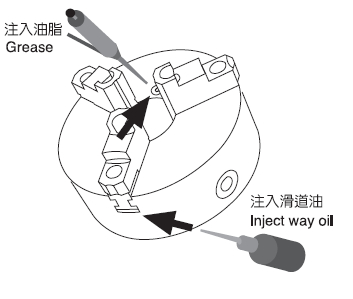

Lack of lubricating oil

Chuck decomposition cleaning various parts of the lubrication

Poor accuracy

Dust accumulated on the bottom jaw and a binding site

The bottom jaw and a fixed screw without locking

Remove the upper and completely clean and to appropriate to the standard torque locking

Poor accuracy

Claw Zi assembly error

In accordance with the assembly number

Poor accuracy

A too high

Correction of a height

Poor accuracy

Chuck diameter and the heart are not allowed

To the deviation correction diameter and end after locking screws