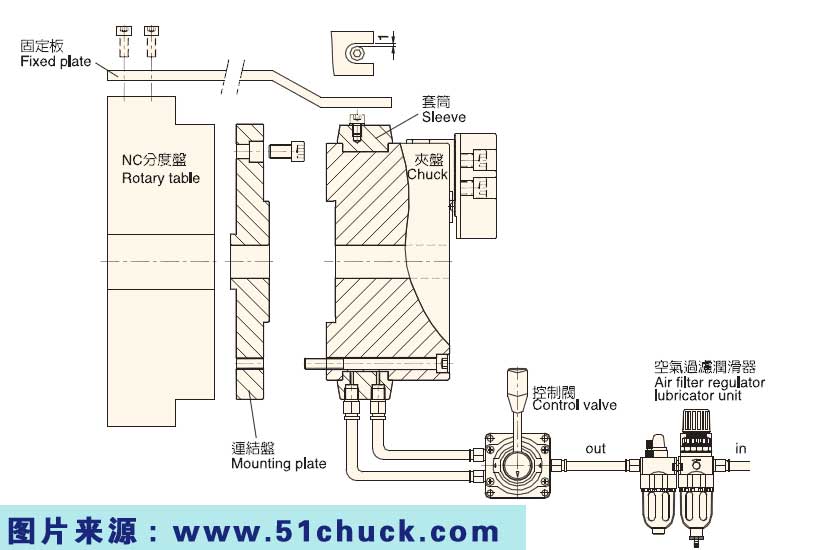

The following installation according to new Kuril pneumatic chuck RT-05 in CNC dividing disk as an example.

2, chuck is fixed on the connecting plate (chuck diameter concentricity and plane deflection correction is required within 0.02mm).

The 3 connecting screws, chuck, please press the set torque locking.

4, such as locking torque is insufficient or too will lead to the occurrence of meaning. Please refer to the specific instructions.

5, to connect the disk fixing sleeve, note: connected with the sleeve can not lock, must be left between the gap above 1mm, plate thickness more than 5mm.

Foreign body in 6, before the dust pipe pipe to clean.

7, careful control valve to connect the air pipe and air filter to filter the moisture and grease lubricator, chuck.

8, during the test run, the pressure is adjusted to 2kgf/cm2 (0.2MPa) after the set, according to the following steps to check.

9, check whether the smooth chuck action.

10, check the moving direction is correct (jaw opening and closing).

11, check the actuator stroke is sufficient (claw trip).

Line 12, check the name parts have no leakage phenomenon.

According to the above matters in check is correct, adjust the required pressure check again.