When oil spill occurs, the decomposition of hydraulic cylinder cleaning and replacement of O ring, must be very careful in dealing with the oil pressure cylinder at this moment, because it is partly made of aluminum alloy.

The hydraulic unit (maintenance of the hydraulic station)

1, clean the oil inlet filter mesh, about 2-3 months time.

2, check the hydraulic oil of about half a year, if has changed, please change.

3, when the operating machinery using the maximum oil pressure and maximum speed, decomposition of inspection of the internal parts must be every year, and replace the oil seal.

4, when the process pressure is too large, will cause the hydraulic cylinder actuator failure and damage, so must adjust the throttle valve to reduce bursting pressure.

5, every week check check valve off device is normal, check method: let the chuck to clamp a round bar after turning off the power supply, check whether the workpiece will be off, not loose said normal function, such as loose said function failure, shall immediately send factory repair.

Use and maintenance of hydraulic chuck

1, the clamping force will change with the kind of oil, a height and other conditions vary. We in the specifications listed in the table below the standard value is based on the situation.

2, the use of standard Taiwan imported soft claws, and measuring the clamping force of the clamping force tester used when placed in the middle position of soft claw height.

3, the use of a lubricating oil or molybdenum disulfide lubricating oil.

4, install the dewclaws, screw locking torque, must be in accordance with the standard torque locking.

5, the list of allowable tension is the maximum allowable tensile plate.

The use of pump oil outflow must have at least 20L/min, control oil pressure must be pumped controller or pressure relief valve controlled separately

The use and maintenance of hydraulic chuck

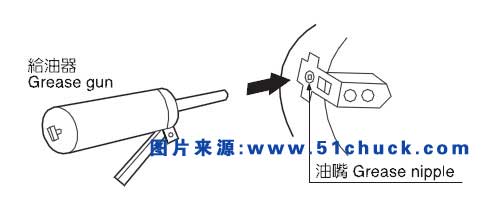

1, in order to use long time still have good accuracy and chuck often, lubrication is important.

2, incorrect or not suitable for lubrication will lead to some problems, such as: low pressure when not out of normal function, reduce clamping force. Holding bad precision, wear and stuck not normal, so we must chuck correct lubrication.

3, the use of a lubricating oil or molybdenum disulfide lubricating oil.

Be sure to air gun or similar tool to clean the chuck body and the slide surface at the end of 4, please.

5, the use of cutting oil with anti rust effect, can prevent the chuck body rust, rust into life will reduce the clamping force, must pay special attention to.

1, but if cutting of rusty iron every two months at least once or several times to thoroughly clean.

2, check the parts without fracture and wear of the situation, serious person immediately replacement.

3, check than after, to oil, to group.